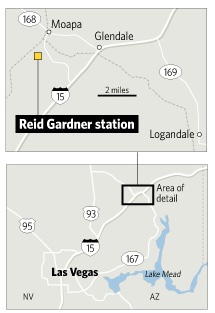

Piles of waste wood and coal wait to be mixed at NV Energy’s Reid Gardner Station coal-fired power plant Wednesday, Nov. 4, 2009 near Moapa.

Tuesday, June 8, 2010 | 2:01 a.m.

NV Energy Tests Wood

NV Energy is testing out a new source of renewable energy: wood. The wood comes from trees that were cut for fire control in an Arizona national forest, and burning it emits less harmful sulfur into the environment than the coal that is traditionally burned.

Sun Archives

Sun Coverage

NV Energy’s experimental use of wood chips in one of its coal plants was a bit of a flop, but the utility and state officials are hoping it will wind up being the first step toward using waste wood that is stacking up in Nevada.

The test, which began late last year, found that wood could be burned to generate electricity, but the timber would need more processing first and possibly a change in plant design to make it worthwhile.

The utility conducted the tests as part of its efforts to find new sources of renewable energy.

NV Energy had hoped that burning waste wood in its Reid Gardner coal plant would provide a cheap way to fulfill part of the state-mandated renewable energy portfolio standard, which requires it to produce 25 percent of Nevada’s electricity from renewable energy resources and energy conservation efforts by 2025.

By the end of this year, 12 percent of the state’s electricity is expected to come from renewable sources.

Legislators and environmentalists at the time of the tests said they would prefer to see a plant specifically designed to use only biomass fuel rather than wood-coal blends. But using the blend was better for the environment than either mining and burning coal or disposing of the wood by burning it in the open, they said. At the plant the emissions from the blend were scrubbed before coming out of the smokestacks.

Prescorched wood, known as wood char, has been used in the fuel mix for U.S. coal plants for several years, but feeding raw wood into the boilers is relatively new, and the tests provided important information. The tests involved feeding raw wood chips of various sizes into the boilers along with coal.

Early attempts with larger wood chips clogged the plant’s pulverizers, so operators switched to a more finely ground wood. That too caused clogging problems, said David Sims, NV Energy renewable energy project development director.

The results were dramatic decreases in plant efficiency, he said. The plant produced 20 to 25 percent less electricity during the wood chip tests than when it burns pure coal, Sims said.

That’s because the pulverizers, designed to crush coal, smashed the comparatively wet wood into giant pancakes. That led to less fuel being pushed into the boilers and periodic shutdowns to clean out the pulp. Because the plant couldn’t run constantly, less electricity was generated.

NV Energy was also underwhelmed by results of emissions monitoring from the plant during the test. Plant operators substituted enough wood for coal to make up about 5 percent of the fuel mix. But the changes in emissions from the plant were negligible, spokesman Mark Severts said.

“We were hoping that the emissions might improve slightly. They did not worsen, but also did not significantly improve.”

Environmentalists, too, were hoping the change would lessen pollution from the plant.

Although the last batch of wood was from Arizona, Nevada has plenty of waste wood. White Pine and neighboring counties have for years been attempting to clear millions of acres of juniper and piñon pine that are encroaching on the historical sagebrush habitat used by sensitive and endangered species and sucking enough water from the ground to lower the water table near thirsty ranches.

There have been a few proposals and tests of biomass-fueled generators in Northern Nevada, including one at a rural elementary school and another by a prison. Both were aimed at reducing the facilities’ utility bills. But the $8.8 million plant at the prison could not cover its expenses, and the equipment is for sale.

The state Forestry Division is looking for someone to take the tons of pulp wood it removes from fire-prone areas each summer. There are about 9 million acres of waste wood and encroaching forest removed to prevent wildfires and preserve sagebrush habitat. So tree clearing activities in the Lake Tahoe area and tree removal in other parts of the state will continue, the division recently announced.

The Forestry Division needs to thin certain areas of forest to reduce the threat of wildfires and to maintain sagebrush habitat for endangered and sensitive species, said Eric Roussel, head of its biomass program.

“With thinning, waste products are developed that are currently rendered unusable and burned on site or sent to landfills due to the limited need in Nevada,” Roussel said. “This wood waste would be a good source of renewable fuel for energy generation.”

NV Energy is interested in biomass technology and may invest in a biomass plant or sign a power-purchase agreement if the right project comes up, Severts said.

That’s one reason NV Energy plant operators haven’t given up on the idea of burning wood in the coal plant.

They’re considering future tests with wood chips ground to sawdust and building a secondary input system that can feed the sawdust directly into the boilers.

Plant managers are also looking more closely at torrefaction, which is basically a fancy type of charcoal. Other coal plants are testing the use of this wood material with mixed results, Sims said.

“The idea is that you could use it in the existing fuel system, because it would theoretically be a crushable material, so you wouldn’t need to build the additional input equipment,” Sims said. “But we’re hearing mixed reviews on torrefaction. Sometimes the material doesn’t dry all the way through, so when it goes through the feed system, it might still have some of the same problems as wood.”

NV Energy isn’t sure it wants more tests. Changes to the plant could be expensive and obtaining permits could be time consuming. But it is looking at what it would need for further tests to be started, Severts said.

Join the Discussion:

Check this out for a full explanation of our conversion to the LiveFyre commenting system and instructions on how to sign up for an account.

Full comments policy